Manufacture Adria is no stranger to the mining community. The company, which started out as an offshoot from another electrical contractor, has been a part of the industry for over a quarter of a century. The expertise that has been harnessed over this time, coupled with the growth and determination that comes with its newly independent status, has resulted in revolutionary new developments, not just for the company itself, but for the mining industry as a whole.

~

Development Manager Rami Hakam says that the opportunity to take the business into a new independent space was a logical and necessary one. “We started the company, and with time, it has evolved. A couple of years ago, part of the management team started to focus on manufacture, and the solution was to run that company as an independent company.”

The resulting rebranding and change of ownership gave Manufacture Adria the freedom to use its previous experience and customers and grow from that strong position. The company could harness the skills that had been developed and provide smart, competitive solutions to its customers. “It allowed the company to be more focused on growth of the manufacturing side, and from a practical standpoint, if you are part of an entity, you don’t have the independence to deal with everybody. For example, our original electrical contracting company – but also other contractors – before, you couldn’t deal with them because they would be in competition with our major shareholder.”

Rami notes that the local environment, as a large mining hub, “was ready for the company,” and that the change in ownership “was seamless really due to the fact that the people that bought the company were the people that were already managing the manufacturing operations.”

One new development was that the company, by listening to the needs of its clients, ensured that each product is specifically tailored and individual. “This company saw the need to start designing equipment custom made. It is now made-to-order for specific applications and for specific mines.” Given the nature of the industry, this was necessary. “Sometimes, equipment for two different mines is different, even if they provide the same function. It can be different to make up for the working environment. The products are designed specifically to the customer’s needs. A lot of what is do cannot be bought off the shelf. The only way to have these products is for someone to design it and build it for you. That is the service we offer our customers. We offer electrical; we offer custom electronic controls, and it is always made specifically for that customer.”

The company has established an engineering procurement system as well as an Enterprise Resource Planning (ERP) system to better manage production and quality control. Rami suggests that, while these have improved the operation, progress is a natural result of building solid working relationships with clients. “Our output has improved, but we always had good customer support and customer satisfaction. We have a loyal (customer) base.”

Trust is a key factor in establishing these relationships. “You know that famous triangle of quality, speed, and price? Wisdom is that you cannot have all three. Well, we discovered that you could. It requires us to take an extra step all the time, and we are always honest and upfront with our customers. We are not selling commodities; we engineer products, and this is part of building relationships with our customers. They are our customers but also our neighbours.”

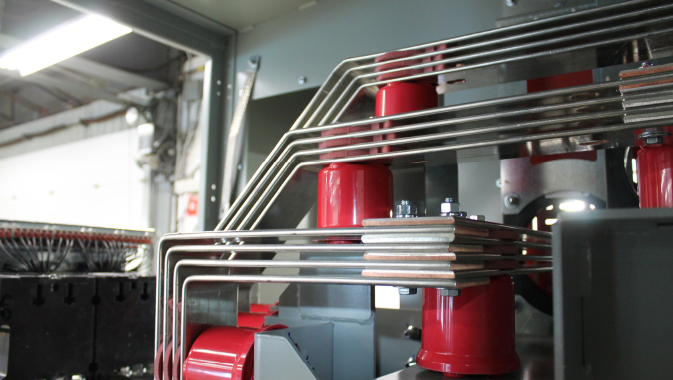

Manufacture Adria, while it offers clients a range of electrical products, is considered a specialist in the design and production of substations. Due to the unpredictable nature of underground mining, the product is a vital aspect of the industry.

“Our best seller is the item that is used the most in a mining operation. You need an electrical infrastructure; everything underground works on electricity. However, the mine is a moving operation. It is not steady. When you build a city, for example, you have the infrastructure, and it doesn’t move, but a mine is a living organism, and it is moving all the time, and the equipment will have to be moved. When you know your equipment, everything that you want, it all has to be in one or two pieces. It has to be ready to go immediately. This is what we are known for – the moveable substation. It is one compact unit and has everything you need. That is our major project and forms the skeleton of mining distribution in general.”

With the pressure on businesses to grow, develop, and move forward, it is natural that advances are also being made the mining industry. Rami identifies a change taking place and says that Manufacture Adria is perfectly placed to lead this development. “One of the biggest transformations is the complete electrification of mines. So, as I said, there is a lot of electrical equipment – drills, lighting, ventilation et cetera. The big ore haulers, such as trucks and loaders, are run on diesel. With the emissions, you need to move large amounts of air, and because of this, it is becoming more expensive to go deeper underground.”

As a response to these rising costs, a pilot project was started in 2012 to work with battery powered equipment. This project resulted in an emerging demand for new equipment, and Manufacture Adria was ready to get involved. “This is equipment that weighs about nine tonnes and moves around four or five tonnes of rock, and it was battery powered. For these, they needed chargers, so we worked with their equipment vendors to develop a charging system. This isn’t just any charger. You need something that will charge batteries but also that the charger can withstand the journey down to make it to the application and then to withstand the mining environment. We have done that.”

New products and developments invariably results in new legislation. Manufacture Adria has identified a need for a concerted, international effort to advance the industry and provide better benefits for clients, employees, and the industry itself. Battery and diesel operated vehicles differ in many ways, and the need for change is not merely limited to fuel. However, these changes should not be seen as a threat to the industry.

“For one thing, it decreases your ventilation costs. You no longer need a huge ventilation shaft. All you need now is to change the air for the people there. Those costs can drop by almost a half or more. There is a group called the Global Mining Group, and its aim is to provide a platform and guidelines for the advancement of mining throughout the world. When you have an international guideline, it is easier to compare projects; it is easier to develop and easier to evaluate projects. We are a contributor to one of the sub-groups that are working towards this. We are looking at developing guidelines for the implementation of battery operated vehicles in underground operations.”

The reasons for these guidelines are many. In addition to cost and efficiency, there is also a human benefit. “Another huge aspect of this is from the miners themselves. They reported an improvement in their working conditions – less noise and less diesel emissions. That was major feedback that came from the operator. They love electrical powered equipment.”

No industry stands still. Advances in technology are assisting in driving underground mining to new levels in terms of productivity, environmental ethics, and working conditions. It is clear that, with over twenty-five years of experience designing, producing and manufacturing products, Manufacture Adria has positioned itself at the cutting edge of these changes.